rAAV Vector Plasmid

This plasmid contains the gene of interest (GOI) flanked by AAV ITRs. The GOI can be a therapeutic gene, a reporter gene, an interfering RNA, or any combination of these molecules as designed. The ITRs are essential for the replication and packaging of the AAV genome.

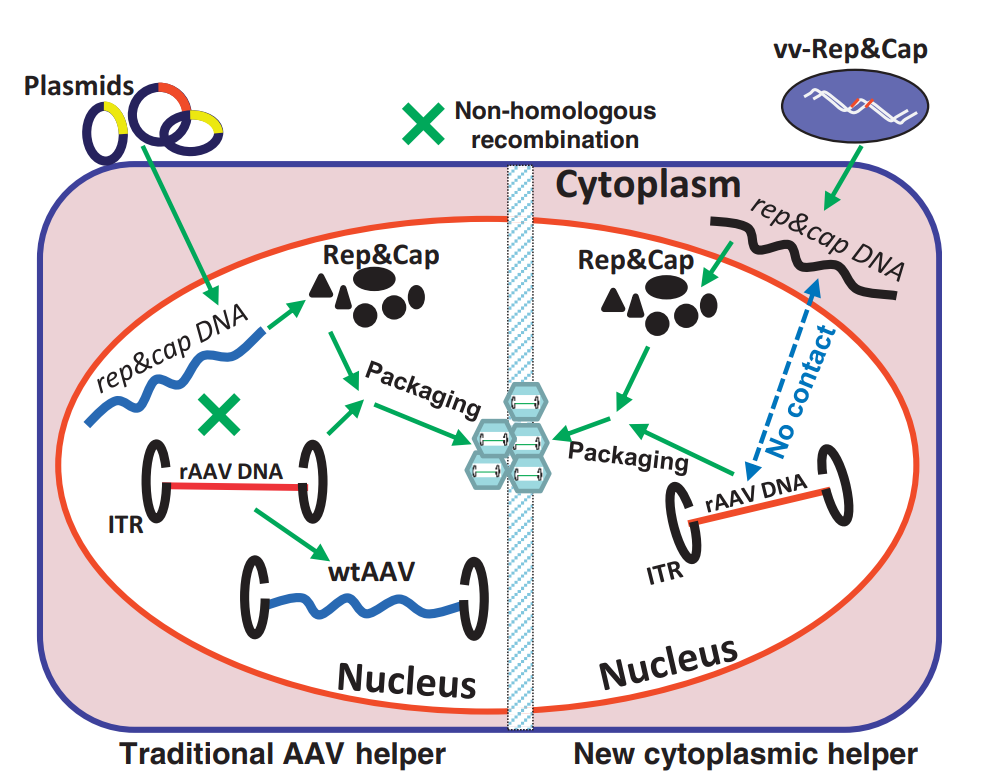

Rep/Cap Plasmid

This plasmid provides the AAV rep and cap genes in trans, which are responsible for the replication of the rAAV genome and capsid proteins, respectively.

Adenoviral Helper Plasmid

The plasmid contains essential adenoviral helper genes, including E2A, E4orf6, and VARNA, which play a crucial role in supporting rAAV genome replication and vector production. The HEK293 host cell supplies other adenoviral helper genes, such as E1A and E1B.

Production Process

The three plasmids are introduced into a packaging cell line, typically within HEK293, to facilitate the production of rAAV vectors. The coordinated expression of AAV rep and adenovirus genes serves to expedite the replication of the rAAV genome. Concurrently, the expression of the Cap gene instigates the formation of vacant rAAV particles. Ultimately, the rAAV genome is encased within these empty particles, thereby yielding rAAV vectors, with the aid of Rep proteins.

Harvesting and Purification

In the context of production systems, rAAV vectors are typically obtained from suspended cell cultures. The purification of the rAAV vector can be achieved through various methodologies, such as ultracentrifugation or chromatography, with the aim of eliminating cellular debris and contaminants.

Quality Control

The final rAAV vector preparation is subjected to comprehensive quality control procedures to affirm its safety and efficacy. These assessments typically encompass the evaluation of vector genome titer, purity, as well as in vitro and in vivo activity.